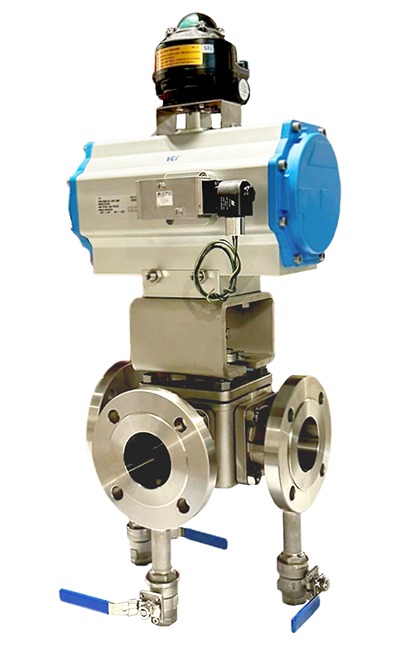

T400 Multi-Ported Ball Valves are used in Oil & Gas applications where flow needs to be diverted, mixed, or isolated between multiple process lines with a single valve. They are commonly installed in sampling systems, chemical injection skids, fuel gas distribution panels, and manifold systems, where space and valve count must be minimized without compromising control. Their ability to handle multiple flow paths within a compact footprint makes them ideal for instrumentation, test loops, and maintenance bypasses, improving efficiency and reducing piping complexity in both upstream and downstream operations.

- Sampling Systems: Allow selection between process streams or routing to sample cylinders without requiring multiple valves or complex piping.

- Chemical Injection Skids: Enable precise control and distribution of injected chemicals to multiple lines from a single valve station.

- Fuel Gas Distribution Panels: Direct gas flow to various burners or equipment safely and efficiently within compact skid layouts.

- Manifold Systems: Provide streamlined control of flow direction between multiple process lines, reducing space and valve count in processing units.

- Instrumentation Loops: Facilitate testing, calibration, or bypass of instruments without interrupting the main process flow.

- Maintenance Bypasses: Simplify temporary flow diversion during equipment servicing or shutdowns, improving operational flexibility.

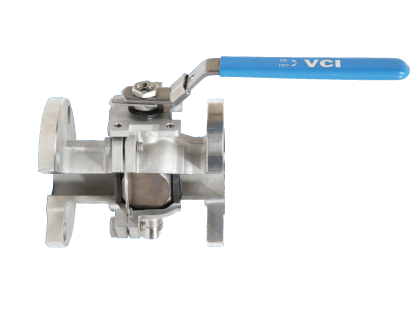

The T400 Multi-Ported Ball Valves are used in the pulp and paper industry to provide streamlined flow control and isolation across multiple process lines within a single compact valve body, reducing piping complexity and installation costs. These valves are ideal for chemical dosing systems, stock distribution lines, effluent handling, and wash water circuits, where multiple flow paths need to be directed, mixed, or shut off without the need for several individual valves. Their robust construction and ability to manage slurries, chemicals, and water-based media make them well-suited for the demanding, often abrasive environments of pulp and paper processing facilities.

- Chemical Dosing Systems: Direct multiple chemical feeds with a single valve, enabling efficient and precise injection into the pulp process.

- Stock Distribution Lines: Route pulp slurry to various processing stages or machines without the need for multiple isolation valves.

- Effluent Handling Systems: Control the flow of wastewater streams from different sections of the mill through a centralized valve.

- Wash Water Circuits: Manage wash water delivery to various cleaning points in bleaching or screening systems using fewer valve assemblies.

- Additive Blending Stations: Allow for controlled mixing of performance additives into the pulp flow with reduced piping complexity.

- Sampling and Test Loops: Enable easy diversion of process flow for quality checks or system monitoring from a single multi-port valve.