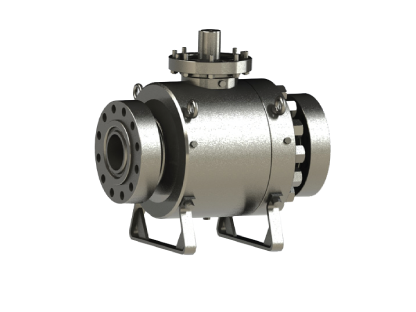

GVS Metal-Seated Trunnion Mounted Ball Valves are used in the petrochemical industry where high temperatures, abrasive media, or corrosive fluids make soft-seated valves unsuitable. These valves are commonly deployed in catalytic reformers, delayed coking units, high-temperature gas or slurry lines, and chemical reactors, where they withstand thermal cycling, erosive particles, and aggressive chemicals. Their hard-faced sealing surfaces and robust construction ensure long-term performance and leak-tight isolation in severe service environments typical of petrochemical processing plants.

- Catalytic Reformers: Withstand high temperatures and corrosive reformate streams while maintaining tight shut-off in continuous processing.

- Delayed Coking Units: Provide reliable sealing in abrasive, high-temperature environments where coke particles and heavy residues are present.

- High-Temperature Gas Lines: Ensure leak-free isolation of process gases in extreme heat conditions where soft seats would degrade.

- Slurry Transport Lines: Handle erosive flow containing catalysts or solid-laden fluids with durable, wear-resistant sealing surfaces.

- Chemical Reactors: Operate under severe chemical exposure and thermal stress, delivering consistent performance in demanding batch or continuous processes.

- Steam and Condensate Lines: Control flow in utility systems supporting petrochemical processes where high-temperature cycling is frequent.

GVS Metal-Seated, Trunnion-Mounted Ball Valves are used in Oil & Gas applications where soft-seated valves would fail due to abrasive media, high temperatures, or contaminated fluids. These valves are commonly found in refineries, gasification plants, offshore platforms, and oil sands operations, where they handle catalyst slurries, sour gas, steam, and solid-laden hydrocarbons. Their robust construction and hard-faced sealing surfaces provide reliable performance and long service life in severe service environments that demand high cycle durability and resistance to erosion and corrosion.

- Refineries: Handle high-temperature hydrocarbon streams and abrasive catalysts in processes such as catalytic cracking and coking units.

- Gasification Plants: Provide tight shut-off and erosion resistance in high-pressure, high-temperature environments with particulate-laden syngas.

- Offshore Platforms: Operate in corrosive, high-pressure environments where durability and resistance to sand, scale, and sour gas are essential.

- Oil Sands Operations: Withstand erosive slurry and heavy crude with entrained solids in upstream production and separation processes.

- Sour Gas Processing Facilities: Offer corrosion-resistant sealing in hydrogen sulfide-rich environments where soft seats would degrade rapidly.

- Steam Injection Systems: Control high-pressure steam in enhanced oil recovery (EOR) applications, requiring metal seating to maintain integrity under thermal cycling.