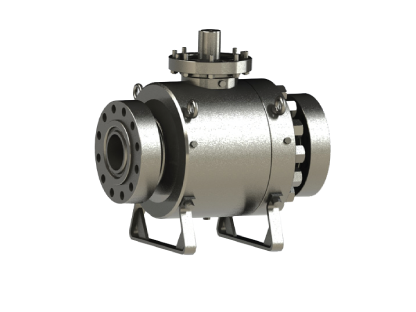

GVS Severe Service Trunnion-Mounted Ball Valves are used in the most demanding Oil & Gas applications where extreme pressures, temperatures, and fluid conditions exceed the capabilities of standard valve designs. These valves are critical in high-pressure gas transmission, abrasive slurry handling, and emergency shut-down systems where reliability and zero leakage are essential for safety and performance. Engineered with enhanced materials, specialized coatings, and metal-to-metal or engineered seat designs, they ensure long-term sealing integrity under corrosive, erosive, or cyclic loading conditions.

- High-Pressure Gas Transmission: Provide reliable isolation in long-distance gas pipelines operating at elevated pressures and requiring zero leakage and high cycle life.

- Abrasive Slurry Handling: Manage erosive mixtures of sand, scale, and hydrocarbons in upstream production or oil sands, where standard valves would rapidly degrade.

- Emergency Shutdown Systems: Ensure fast, fail-safe closure in critical isolation scenarios, often integrated with high-integrity pressure protection systems (HIPPS).

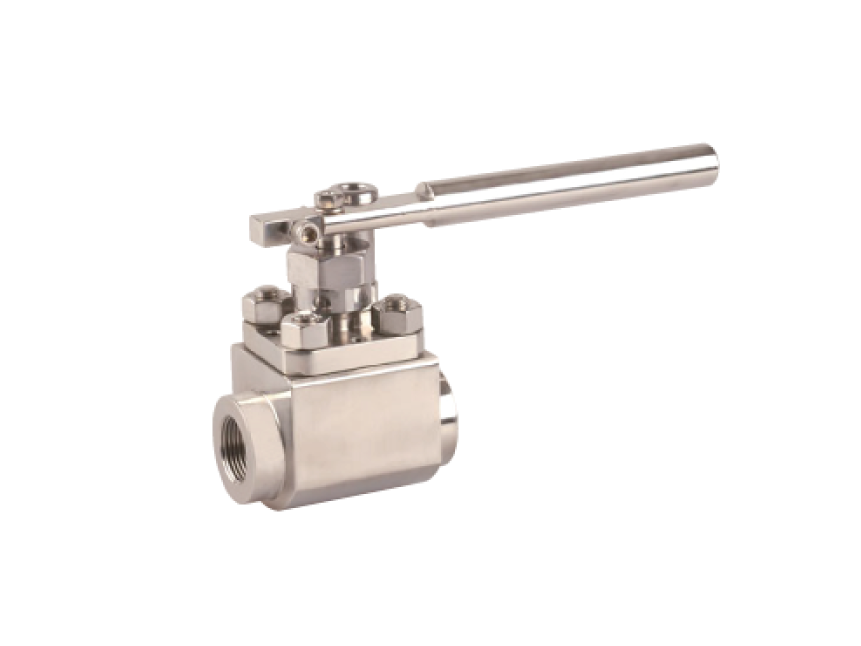

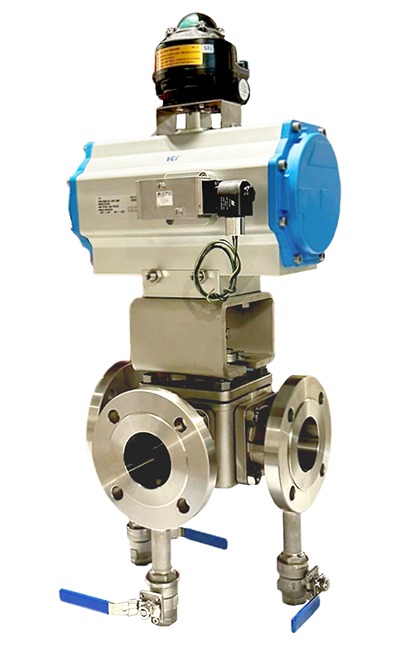

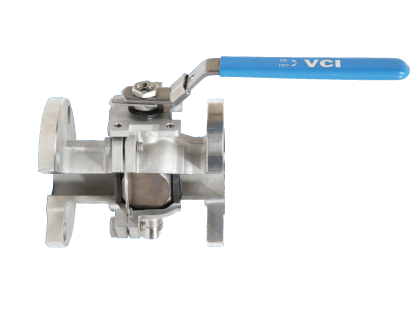

GVS Severe Service Trunnion Mounted Ball Valves are used in the petrochemical industry for critical isolation and flow control in the most demanding operating conditions, including high-pressure, high-temperature, and aggressive chemical environments. These valves are commonly found in hydrogen reforming units, polymer production lines, acid handling systems, and high-cycle automated processes, where standard valves would fail due to erosion, corrosion, or thermal fatigue. Engineered with specialized coatings, metal-to-metal seating, and robust materials, they ensure long-term sealing integrity, safety, and operational reliability in mission-critical petrochemical applications.

- Hydrogen Reforming Units: Deliver high-integrity shut-off under extreme pressures and temperatures in hydrogen-rich, corrosive environments.

- Polymer Production Lines: Handle high-viscosity, abrasive, or chemically reactive media where standard valve components would quickly degrade.

- Acid Handling Systems: Provide corrosion-resistant isolation in lines carrying aggressive acids such as sulfuric or hydrochloric acid.

- High-Cycle Automated Processes: Withstand frequent actuation and thermal cycling in continuous or batch operations requiring tight, repeatable sealing.

- Dehydration and Amine Units: Maintain leak-tight performance in systems exposed to amine degradation and high-temperature regeneration cycles.

- Critical Safety Isolation Points: Serve as last-line barriers in high-risk applications where failure could result in hazardous release or process disruption.