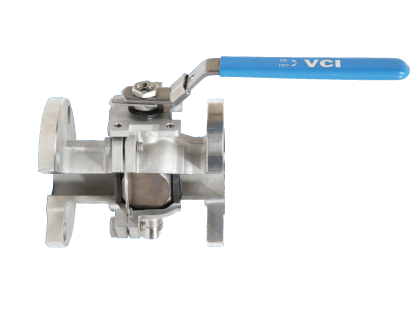

The Series 11F Instrument Isolation Valve is used in the food and beverage industry to provide compact,

sanitary isolation for gauges, sensors, transmitters, and sampling devices without disrupting production.

Its wafer-style design minimizes dead space, making it suitable for fermentation tanks, pasteurization

systems, brewery and distillery process lines, and CIP/SIP loops, where cleanliness and hygiene are

paramount. By allowing instruments to be safely removed, calibrated, or replaced while maintaining

process integrity, the 11F valve supports continuous, contamination-free operation in high-purity food

and beverage environments.

-

Fermentation Tanks:

Allow safe isolation and removal of pressure or temperature sensors without interrupting fermentation.

-

Pasteurization Systems:

Enable quick servicing of instrumentation while maintaining sanitary conditions in heat treatment lines.

-

Brewery and Distillery Process Lines:

Provide clean, compact shut-off for gauges and meters in wort, mash, or distillation circuits.

-

CIP/SIP Loops:

Isolate monitoring devices during cleaning or sterilization to protect sensitive instruments.

-

Beverage Filling Lines:

Facilitate maintenance of flow meters or pressure transmitters without halting packaging operations.

-

Dairy Processing Equipment:

Permit hygienic isolation of sensors in milk, cream, or yogurt processing lines to ensure compliance with food safety standards.

The Series 11F Instrument Isolation Valve is used in the pharmaceutical industry to provide compact,

sanitary isolation of process instrumentation such as pressure gauges, transmitters, flow meters, and

sampling devices. It is commonly applied in bioreactors, fermentation vessels, purified water systems,

and CIP/SIP loops, allowing instruments to be removed, calibrated, or serviced without interrupting

sterile production. Its wafer-style design and clean flow path make it ideal for high-purity applications,

helping maintain product integrity while minimizing dead space and contamination risk.

-

Bioreactors:

Allow safe isolation and removal of sensors or gauges for calibration without disturbing sterile fermentation conditions.

-

Fermentation Vessels:

Provide sanitary shut-off for instrumentation during maintenance while preserving batch integrity.

-

Purified Water Systems:

Enable calibration or replacement of flow and pressure instruments without contaminating high-purity water loops.

-

CIP/SIP Loops:

Isolate monitoring devices during cleaning or sterilization cycles to protect sensitive components.

-

Filling and Packaging Lines:

Allow quick service of instrumentation in aseptic filling systems without halting production.

-

R&D Pilot Systems:

Facilitate frequent instrument changes and testing in small-scale pharmaceutical development setups.

GVS 11F Instrument Isolation Valves are used in the automotive industry to provide compact, reliable

shut-off for instruments, gauges, and sensors during maintenance, calibration, or testing. Their

lightweight, wafer-style design makes them ideal for engine and powertrain test rigs, fuel system

monitoring stations, emissions measurement equipment, and hydraulic or pneumatic test benches,

where space is limited, and frequent instrument isolation is required. These valves help ensure accurate

readings, protect sensitive measurement devices, and allow for quick removal or replacement without

disrupting the entire system.

-

Engine and Powertrain Test Rigs:

Allow precise isolation of measurement devices during engine or drivetrain performance testing without system depressurization.

-

Fuel System Monitoring Stations:

Provide safe shut-off for pressure and flow sensors in fuel delivery systems during calibration or maintenance.

-

Emissions Measurement Equipment:

Enable quick isolation of gas analyzers and sampling devices to protect against contamination or damage.

-

Hydraulic Test Benches:

Isolate gauges and transducers in high-pressure hydraulic circuits to prevent overloading during system adjustments.

-

Pneumatic Test Benches:

Control air supply to instrumentation for brake, suspension, or component testing while allowing safe service access.

-

Cooling System Test Stands:

Facilitate the removal and calibration of temperature or pressure sensors in coolant flow lines without interrupting testing.